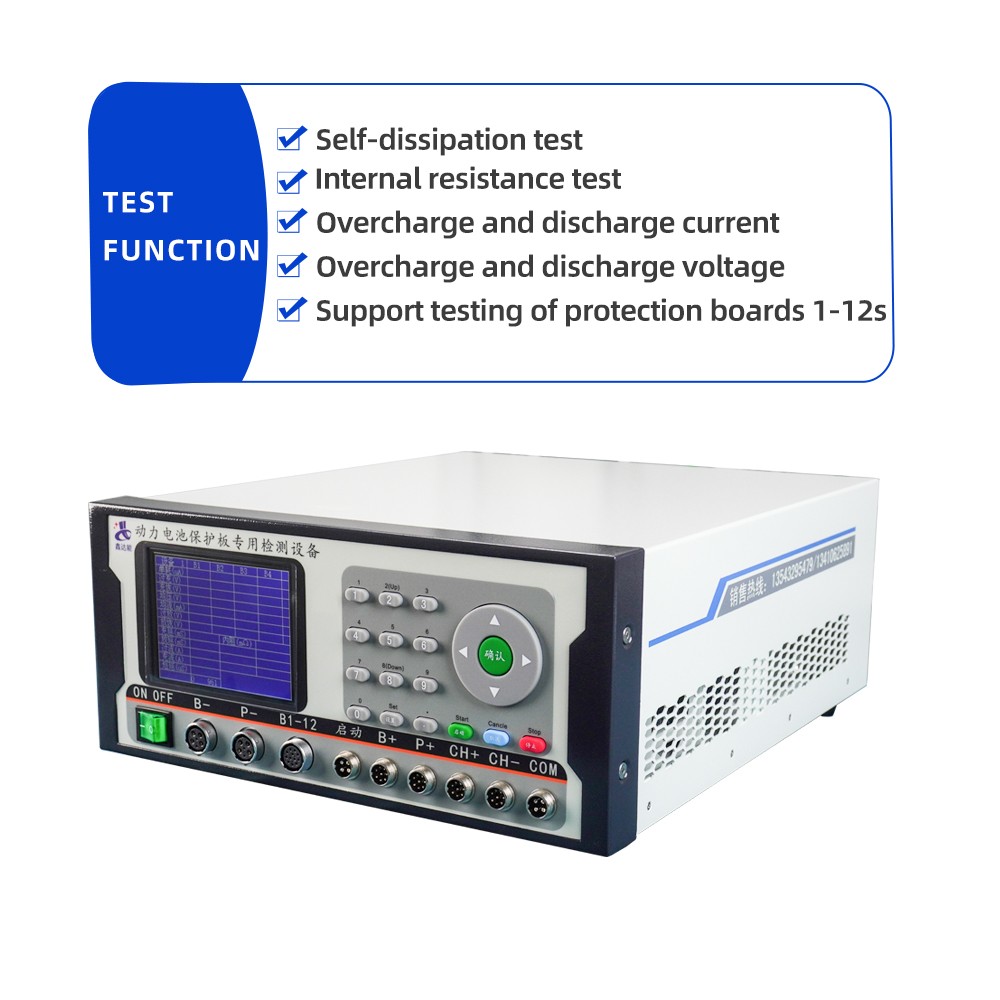

PBTS(M)-12S120-Lithium Battery Protection Board (BMS) Tester

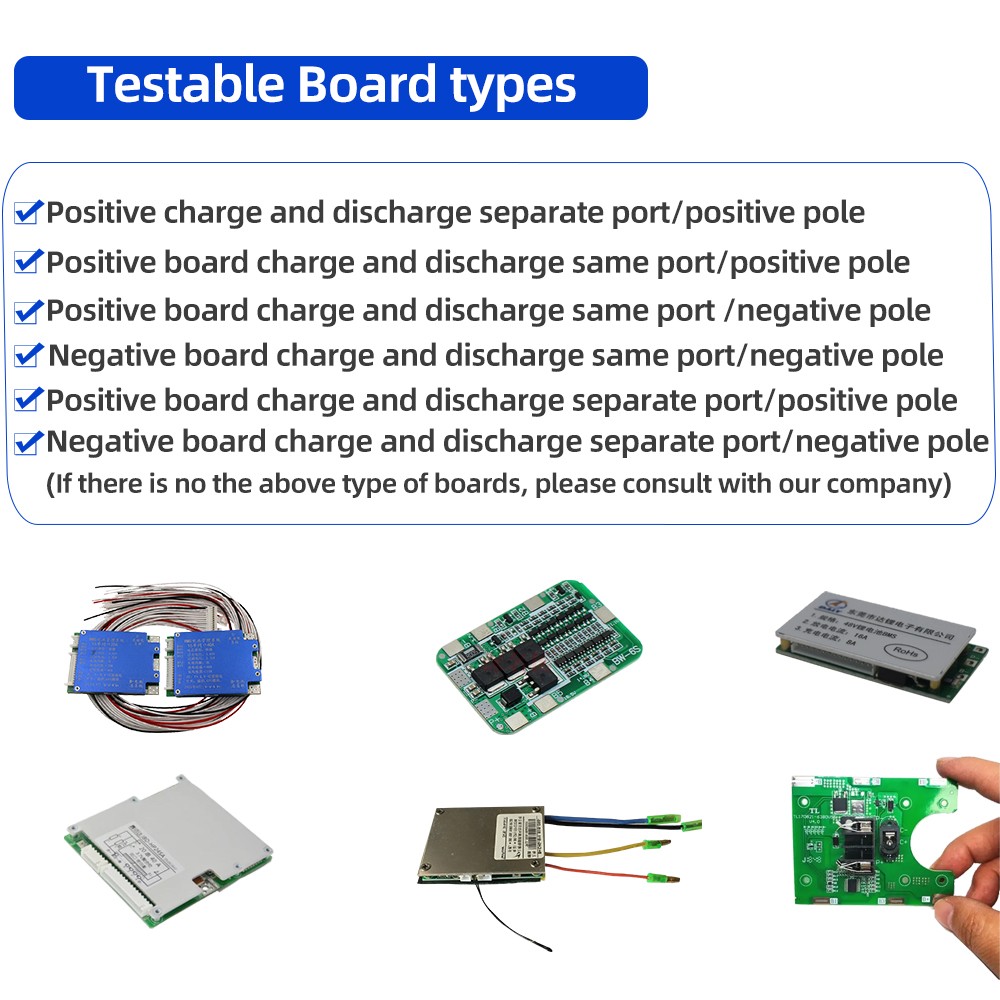

PBTS(M)-12S120-Lithium Battery Protection Board (BMS) Tester applied to lithium battery protection plate safety testing, testing the protection plate functional indicators are within reasonable parameters, providing staff with a set of testing standards, improving production efficiency, and facilitate quality control. Compatible with the common types of protection plate on the market: positive with the port (split port), negative with the port (split port), positive charging protection negative discharge protection, and so on.

Scope of application

Applied to lithium battery protection plate safety testing, testing the protection plate functional indicators are within reasonable parameters, providing staff with a set of testing standards, improving production efficiency, and facilitate quality control. Compatible with the common types of protection plate on the market: positive with the port (split port), negative with the port (split port), positive charging protection negative discharge protection, and so on. The product is mainly used in production testing, incoming material testing, quality control, R & D testing, etc.

Equipment environmental requirements and technical parameters

Power supply: AC voltage 220V ±10% , frequency: 50Hz ±10%;

Ambient temperature: 10 ~ 45 ℃;

The environment without strong vibration, no corrosive gases and flammable and explosive gases exist.

Mode Introduction

Rapid test: according to the design parameters of the protection board, the upper limit / lower limit of the output design parameters of the device for rapid testing, to facilitate the protection board manufacturers and power battery manufacturers large-scale rapid testing and shipment, applicable to a variety of hardware programs and part of the software program protection board test.

Accurate testing: can accurately detect the precise value of the functional parameters of the power battery protection board (error of±5mv), to facilitate the debugging and development of samples, to provide R & D personnel with a set of standards for rapid testing.

Equipment test items

| Name | PBTS(M)12-120 |

| Number of test strings | 1-12S |

| Basic functions | Internal resistance test |

| Individual Overcharge and over discharge voltage | |

| Individual Overcharge and Discharge Recovery Voltage | |

| Overcharge/discharge protection delay | |

| Charge/discharge protection current | |

| Charge/discharge over current delay | |

| Single secondary overcharge and over discharge delay | |

| Special test items | Single section self-consumption test |

| Equalizing current and equalizing voltage | |

| Test Order Support Adjustment | |

| Test program startup | Support barcode scanning self-start/manual start |

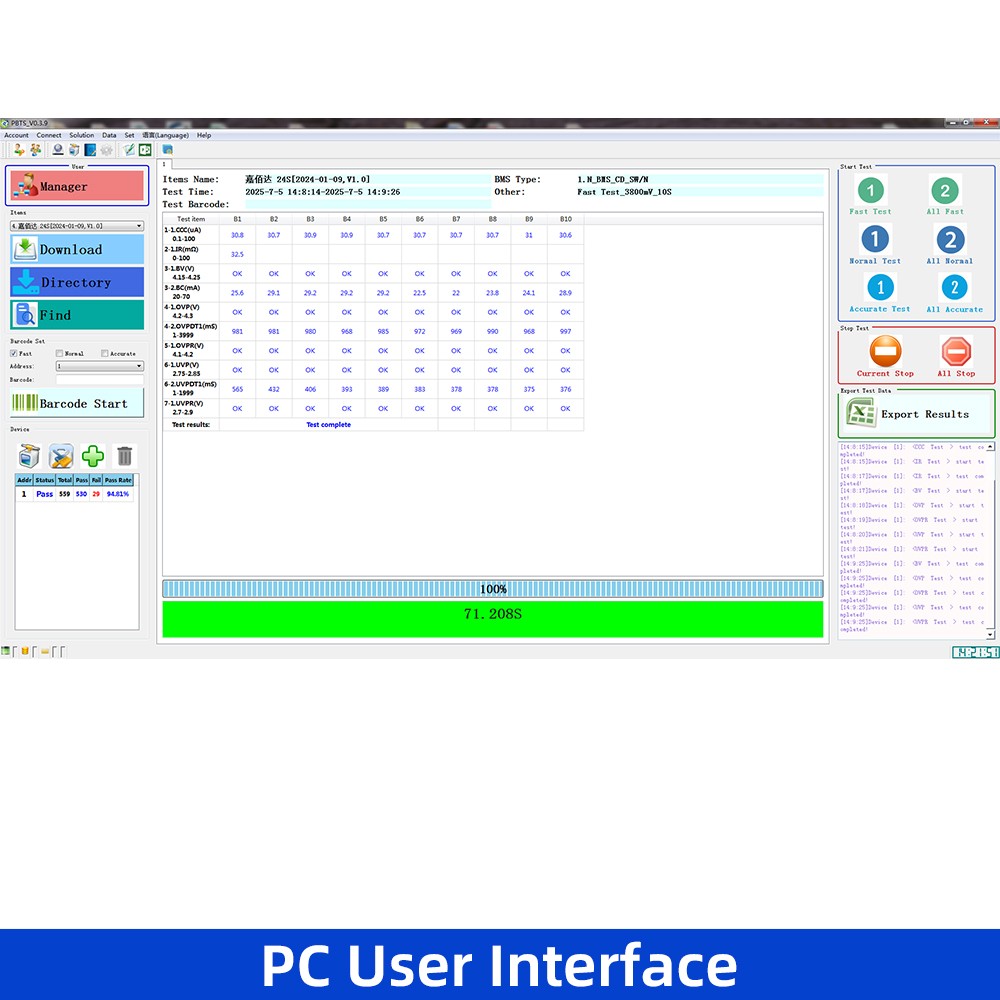

| Test Data | Data sheets can be generated and saved for easy product traceability |

| Application | Measurement of lithium battery protection plate of ternary material, lithium iron phosphate, lithium cobalt, lithium manganese and so on. |

| Protective function | Hardware boards and most software boards (special software boards BMS need to communicate) |

| Module | High current module: current level is 120A, current accuracy ±0.1A |

| Voltage module: programmable output 0.5-5V, accuracy ±5mV | |

| Short-circuit module: super capacitor instantly provides 400A short-circuit current, test out the short-circuit delay time |

Technical Parameters

| Project Type | Range | Resolution |

| Voltage Reference | 3.8/3.0V(Ternary/Lithium Iron) | 1mV |

| Overcharge protection voltage | 0.5-5V | 1mV |

| Overcharge protection release | 0.5-5V | 1mV |

| Over discharge protection voltage | 0.5-5V | 1mV |

| Over discharge protection release | 0.5-5V | 1mV |

| Overcharge/discharge protection delay | 0-20S | 1ms |

| Overcharge current protection value | 3-60A | 0.1A |

| Over discharge current protection value | 3-120A | 0.1A |

| Overcurrent protection delay | 0-10S | 1ms |

| Equalized turn-on voltage | 0.5-5V | 5mV |

| Equalized turn-on current | 0-200mA | 1mA |

| Self-consumption | 0-500uA/0.5-200mA | 1uA/1mA |

| Main circuit internal resistance test | 0-200mΩ | 1mΩ |

| Short circuit protection | 0-9999uS | 1uS |

| Online mode | USB-RS232 serial port communication | |

Software component

Upper computer software: running on the computer, coordinating and controlling the entire test system, completing data acquisition and collation, generating test reports, the test software system has independent intellectual property rights, the software system is fully functional, according to the user-defined specifications to determine the test results pass/fail; the test system in the form of Excel files to locally save all the test results information.

Product logistics packaging

a. Are you a manufacturer or a trading company?

We are a professional lithium battery tester equipment manufacturer with our own factory, which can guarantee product quality and best price.

b. What you can buy from us

PBTS series Protection board tester, BTS series comprehensive tester, BCDS series charge and discharge aging cabinet, BDS series discharger

c. How do we ensure quality

Before mass production, it is always a pre-production sample; before shipment, it is always a final inspection.

d. If I want to customize the instrument, how long is your delivery time and how long does it take

1. If it is in stock, it is 5-10 days.

2. We can provide customized services to customers. According to the specifications of the customized instrument, it usually takes 30-60 days.

e. What is the delivery method of the parcel?

1. Standard export wooden box packaging

2. Express, air freight, sea freight According to customer requirements, find the most suitable way.

Navigation

NEWS

- Application fields and development trends of lithium battery sorting machines

- The working principle and advantages of lithium battery sorting machine

- Advantages and application scenarios of lithium battery welding machines

- Working principle, product types and characteristics of lithium battery welding machines

- Application scenarios and development trends of lithium battery sorting machines

Contact Us

Company:Shenzhen Xindaneng Electronics Co., Ltd.

Name:Miss Doris

WhatsApp:8618923758616

Email:sales1@xdndz.com

Add:Room H, 21st Floor, Block A, Building 1, Anhongji Tianyao Plaza, Daling Community, Minzhi Street, Longhua District, Shenzhen, China