Battery Pack Testing Solution for Electric Forklifts

In the daily operation of electric forklifts, the efficient and stable operation of lithium batteries is crucial. However, the current application of lithium batteries in electric forklifts faces many challenges. First, it is difficult to accurately control the battery life and charging and discharging efficiency. Frequent interruptions of forklift operations due to power estimation errors greatly affect the efficiency of logistics operations; second, the problem of differences in the consistency of battery packs is prominent. The performance degradation of some single cells will accelerate the loss of the entire battery pack and shorten the service life; third, safety hazards cannot be ignored. Lithium batteries may be overcharged, over-discharged, and overheated during the charging and discharging process. Therefore, the inspection and testing of lithium battery packs at the factory is crucial.

Shenzhen Xindaneng Electronics Co., Ltd. was established in 2015. It has many professional lithium battery equipment R&D engineers who are at the leading level in the industry. Since its establishment, the company has been focusing on the research and development of a series of lithium Battery testing equipment such as battery Protection board testers, lithium battery charging and discharging aging cabinets, and lithium battery finished/semi-finished battery comprehensive testing equipment. Mainly for lithium battery and protection board manufacturers, it has provided instrument testing solutions for many well-known companies.

Related product recommendations

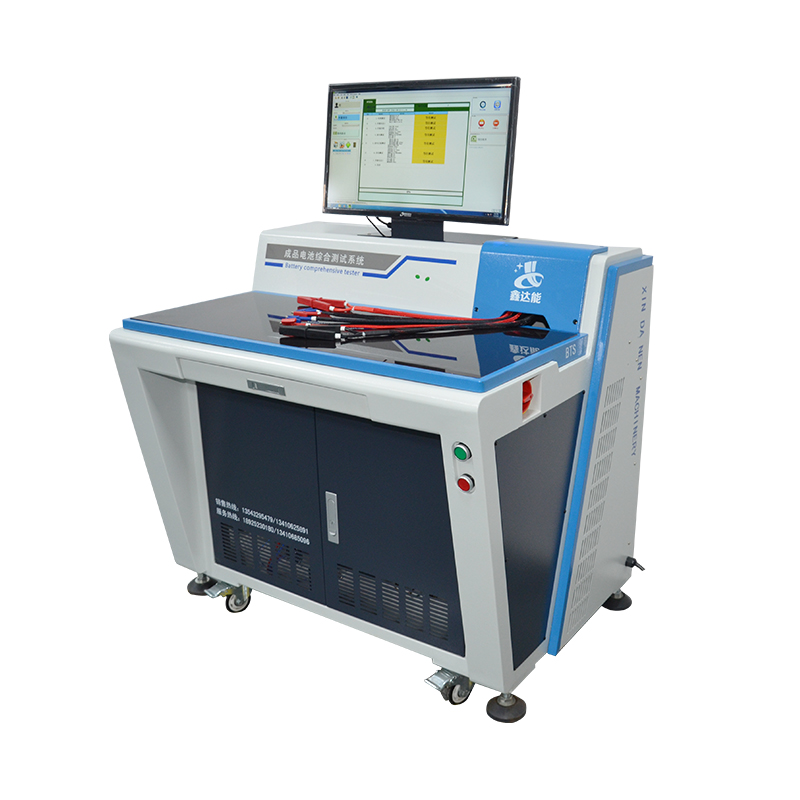

| BTS100-20-120-lithium battery comprehensive tester | PBTS(M)-16S120-Lithium Battery Protection Board (BMS) Tester |

Navigation

News

- Application fields and development trends of lithium battery sorting machines

- The working principle and advantages of lithium battery sorting machine

- Advantages and application scenarios of lithium battery welding machines

- Working principle, product types and characteristics of lithium battery welding machines

- Application scenarios and development trends of lithium battery sorting machines

Contact Us

Company:Shenzhen Xindaneng Electronics Co., Ltd.

Name:Miss Doris

WhatsApp:8618923758616

Email:sales1@xdndz.com

Add:Room H, 21st Floor, Block A, Building 1, Anhongji Tianyao Plaza, Daling Community, Minzhi Street, Longhua District, Shenzhen, China